Recycling Technologies for Radiators

Radiators are typically made from valuable metals such as aluminum and copper. These metals play a significant role in the recycling process and support environmental sustainability. Mizar has developed specialized machines to optimize radiator recycling processes.

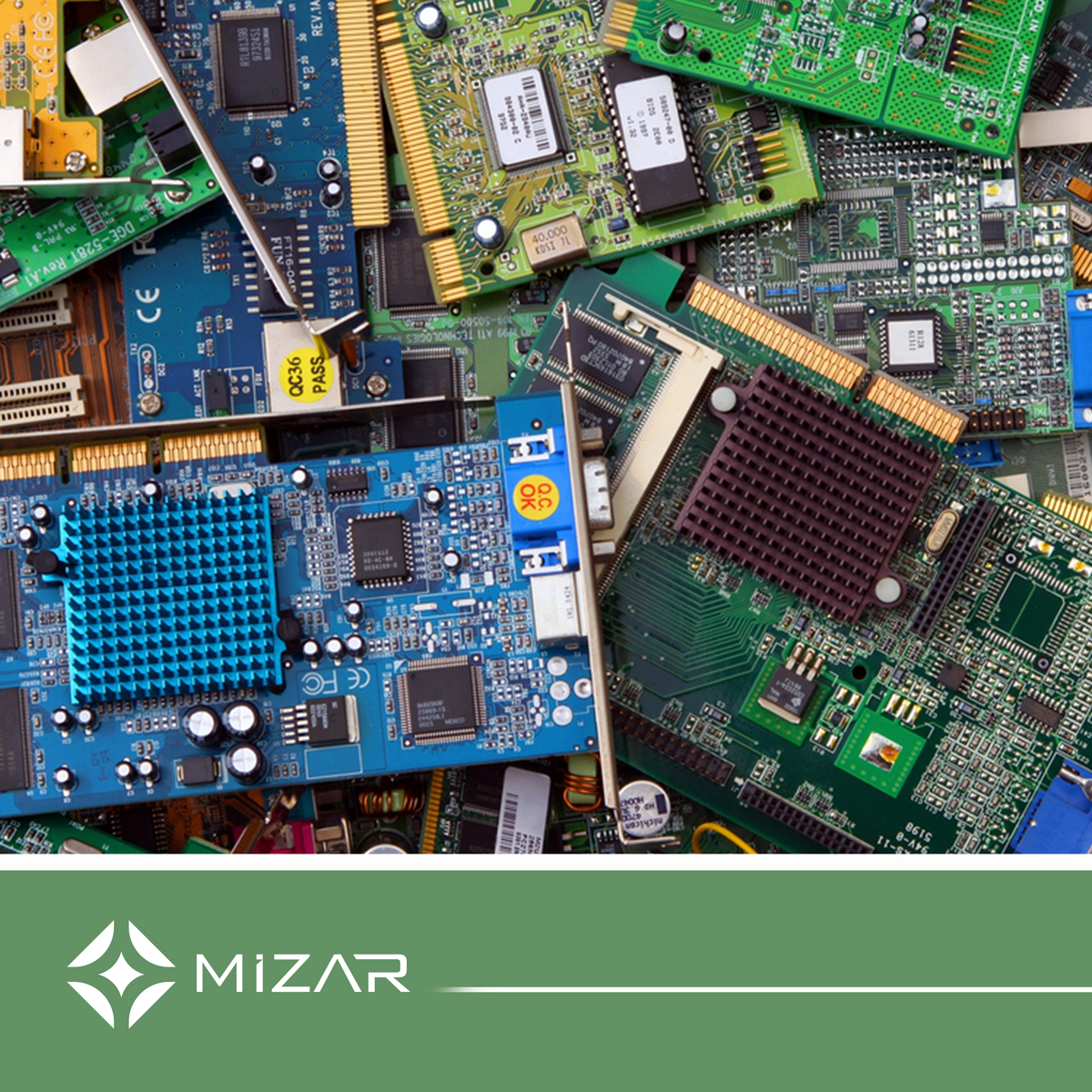

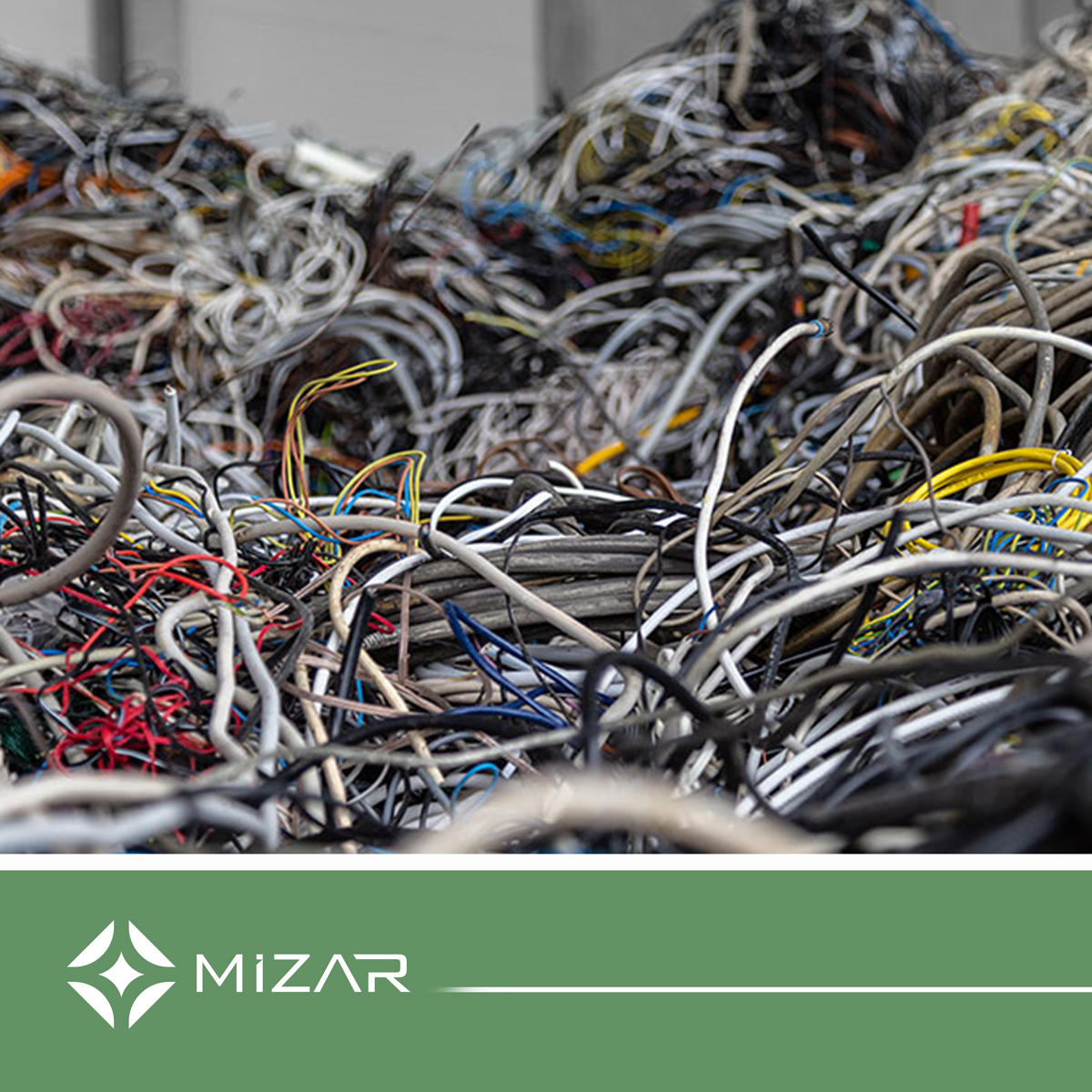

The recycling process begins with the shredding of radiators using specialized machines. Double-shaft shredders effectively break down radiators into small pieces, allowing the metals they contain to be exposed. This stage is crucial for preparing the separation of aluminum and copper from plastics and other materials.

The shredded materials are then directed to granulators. At this stage, the materials are transformed into fine and homogeneous particles. Mizar's recycling machines are optimized to ensure high-purity metal separation. Magnetic separators are used to separate aluminum and copper from plastics, thereby increasing the recycling rate.

Environmental factors must also be considered in radiator recycling. Some harmful substances found in radiators are safely separated during the recycling process, minimizing their negative impacts on the environment. Mizar's machines are designed to operate with energy efficiency, providing cost advantages for businesses.

In conclusion, Mizar's radiator recycling solutions enhance the recovery of valuable metals while supporting environmental sustainability. Radiator recycling is a critical step in waste management, contributing to the conservation of natural resources and energy savings.