Recycling Technologies for Precious Metals

Precious metals are among the most important components of the recycling industry. Metals such as gold, silver, platinum, and copper are not only of high economic value but also limited resources, making recovery processes critically important. Mizar has developed specialized machines to enhance the recovery of precious metals.

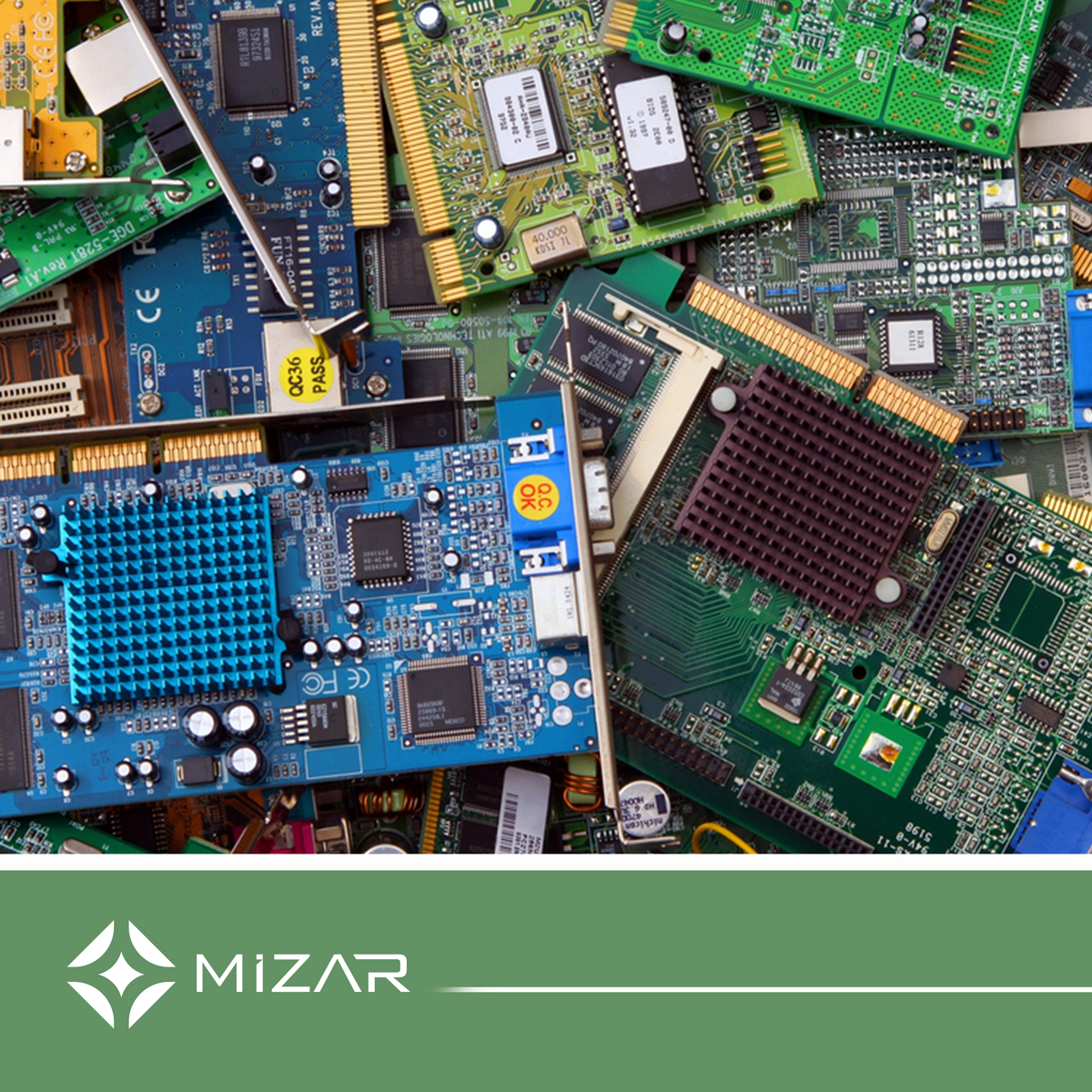

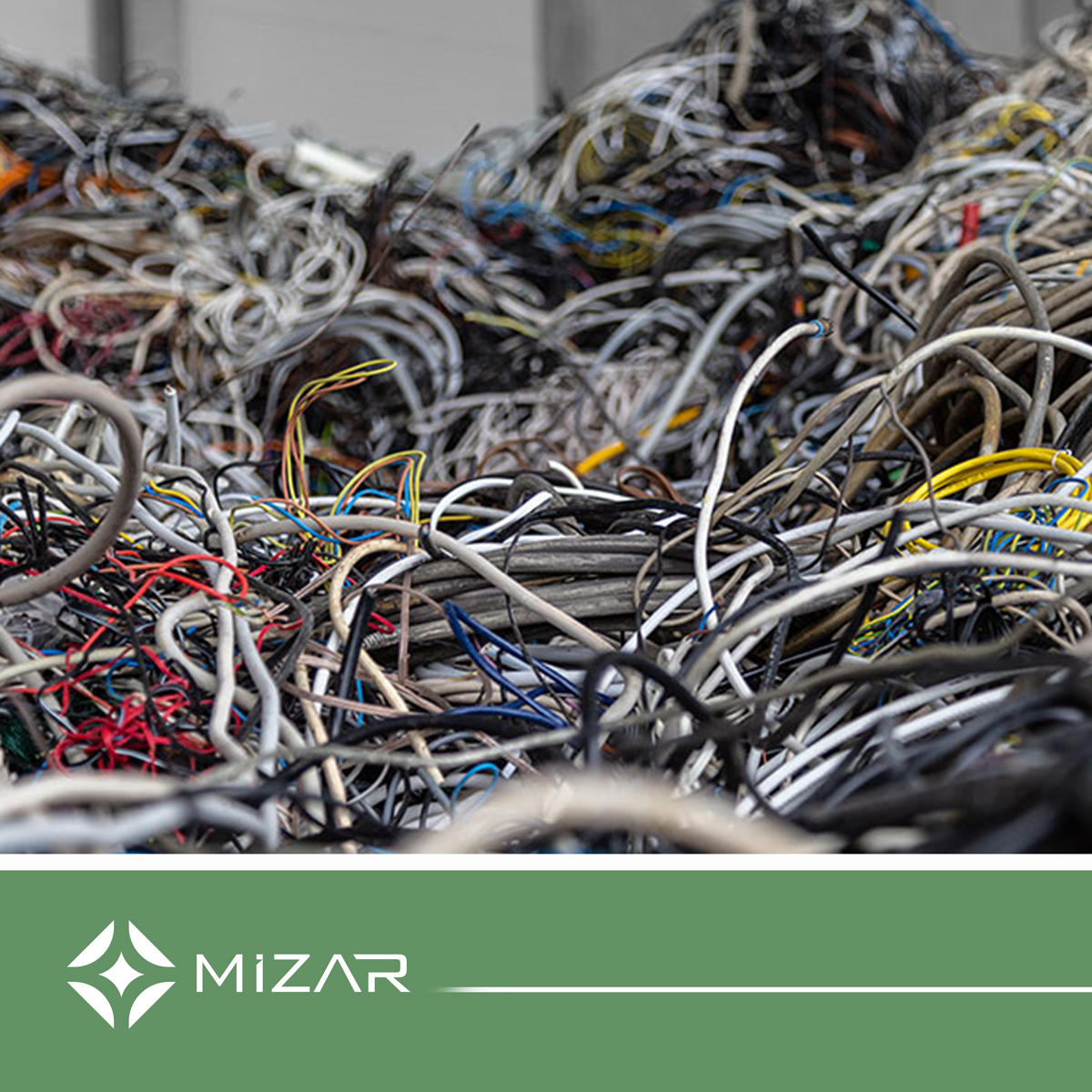

The recycling process begins with the accurate separation of waste materials containing precious metals. In this stage, waste materials are broken down into small pieces using double-shaft shredders. This pre-processing increases the efficiency of the recycling operation and makes it easier to access valuable metals. The shredded materials are then directed to granulators for further refinement.

Mizar's recycling machines employ various technologies to ensure the high purity of metal separation. Magnetic separators play a critical role in separating metals such as copper and aluminum from plastics and other contaminants. Additionally, densimetric separators utilize differences in density among metal components to achieve even greater purity.

Environmental sustainability is also an important factor in the recycling of precious metals. Mizar's machines minimize negative environmental impacts by safely managing harmful chemicals during the recycling process. This creates a safer working environment for both businesses and nature.

In conclusion, Mizar's recycling solutions for precious metals support not only economic benefits but also environmental sustainability. The recycling of precious metals is a critical step in conserving natural resources and enhancing energy efficiency, contributing to a circular economy.