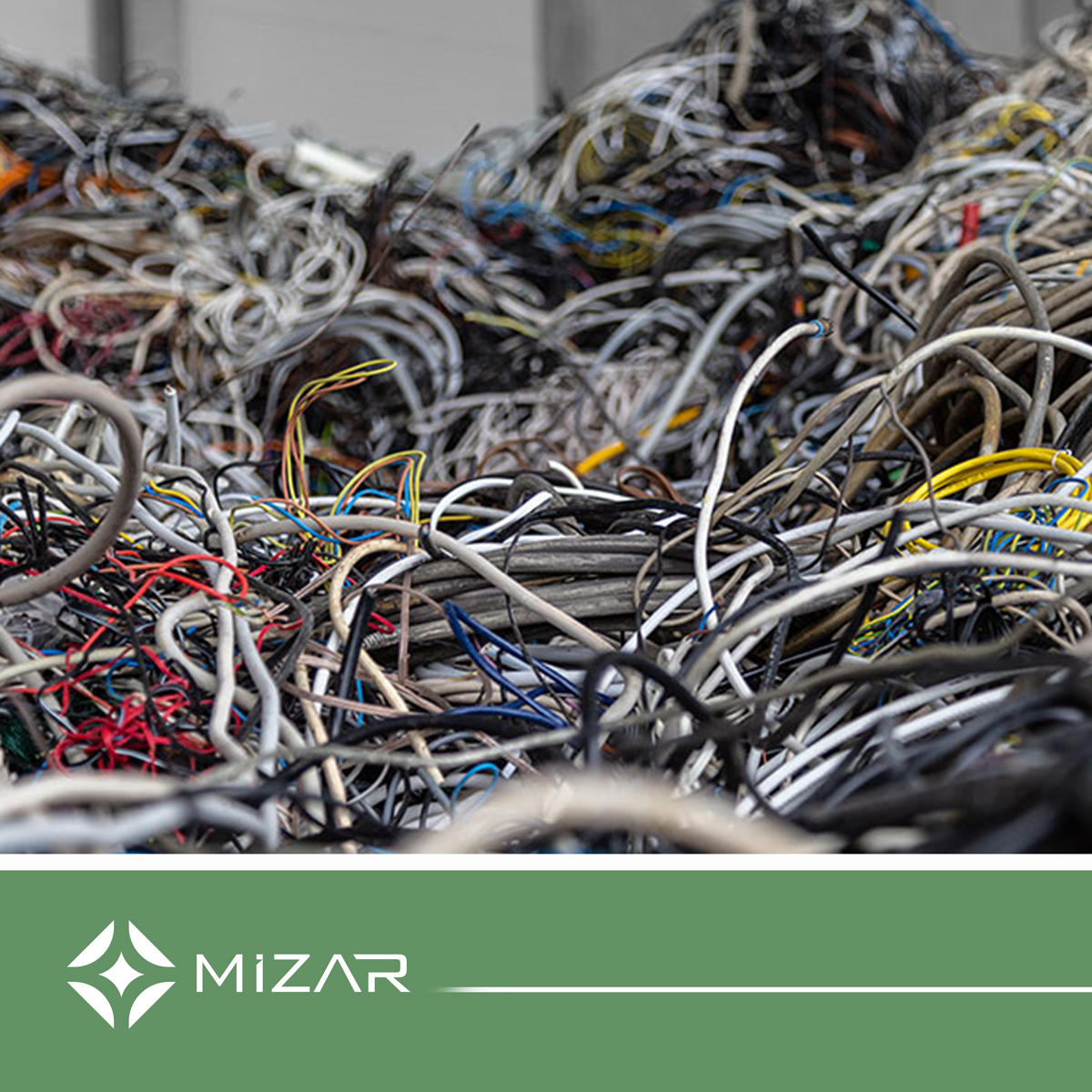

Recycling Technologies for Cables

Cables are among the most commonly encountered materials in the recycling industry, with significant potential for recovery. Cables containing copper and aluminum, in particular, offer great opportunities for the recovery of these metals. The cable recycling machines developed by Mizar efficiently process cables to achieve the high-purity recovery of valuable metals contained within. The primary goal of the recycling process is to separate copper and aluminum from the plastics in the cables and make these metals reusable.

In the initial stage, cables are shredded using double-shaft shredders. This process allows for the exposure of metals within the cable and reduces them to ideal sizes for subsequent steps. Double-shaft shredders not only break the cable into small pieces but also facilitate the separation of metals from plastics. The shredded pieces are then transferred to granulators. The granulation process ensures the complete separation of metals within the cable. At this stage, additional technologies such as magnetic and densimetric separators are employed to enhance the purity of valuable metals like copper and aluminum.

Mizar's machines are designed to operate with energy efficiency and low costs. Moreover, thanks to PLC-controlled automation systems, the recycling process is fully automated, leading to savings in labor costs. These machines offer high capacity for cable recycling and can handle different types of cables. For example, cables consisting of thin copper wires require special attention during the granulation process. Our machines are optimized for precise processing and high-purity metal recovery.

In conclusion, Mizar's cable recycling solutions provide both environmental benefits and economic gains for businesses. The recovery of metals like copper and aluminum from cables contributes to the conservation of natural resources while reducing the need for new raw materials.